Reducing Our Carbon Footprint – NOW

Many in the shipping industry are waiting with bated breath to see which alternative fuel system will be the best one going forward. In a past article on shipping decarbonization by Francesco Bellusci, Scorpio Ship Management’s Managing Director, he discussed the main four alternative fuels that the industry is considering: Biofuel, Methanol, Ammonia, and Hydrogen. Each of these have significant limitations and obstacles in implementation and/or transport. Electric engines, he explained, are not considered an option in shipping due to the low power output, the incredible size and weight of battery storage, and the exorbitant price. Wind power has been making news lately, however, for the size and weight of a tanker ship, the onboard sails are not producing enough power to make a significant impact. Therefore, most shipping companies have been in a holding pattern waiting for improved technologies to make an alternative fuel source a viable and cost-effective alternative.

Unfortunately, this ‘wait and see’ strategy is not conducive to innovation, nor is it getting us closer to the IMO’s Net Zero target by 2050. In the meantime, Scorpio has been actively researching and investing in ways to decrease emissions and increase fuel efficiency with its current fleet, in order to make a difference now.

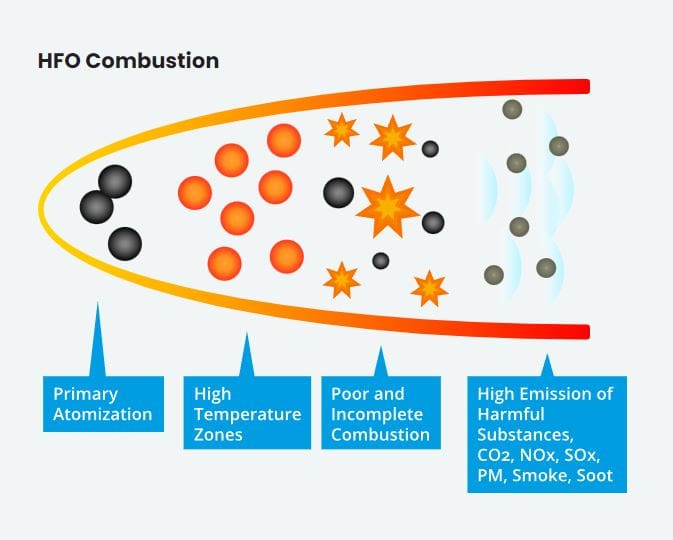

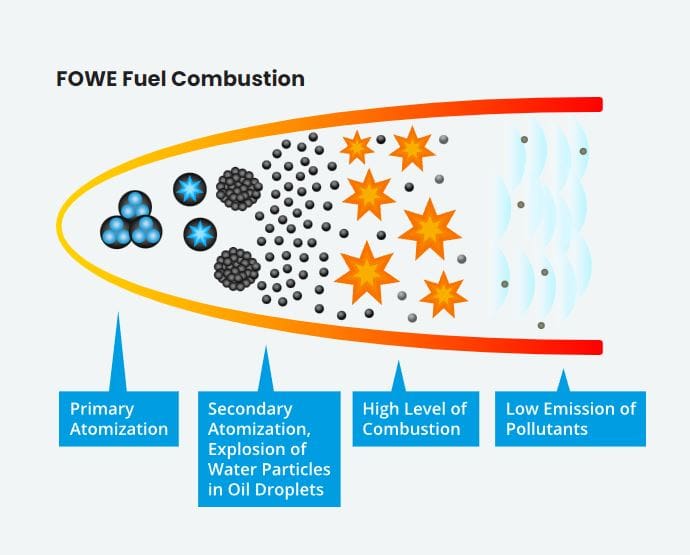

One such company, Fowe Eco Solutions Ltd. (“FOWE”), has developed a fuel cavitation technology that uses static pressure to create stable, emulsified fuel or oil blends without needing any harmful chemical additives or stabilizers, and it is easily installed on current heavy fuel engines. The result of this emulsion is more efficient, cleaner burning fuel with greatly reduced sulfur and nitric oxide emissions, and it also avoids the engine-clogging polymer bonds and free radicals that regular fuel produces. This means that in addition to fuel savings from increased efficiency, there is less engine wear and lower maintenance costs.

FOWE’s Cavitech™ device has been tested in numerous applications for heavy engine use, including oil refineries and marine engines. The tests resulted in 8-10% better fuel combustion and a drastic decrease in greenhouse gas emissions. According to the company, recent tests conducted at the Alfa Laval Test and Training Centre in Aalborg, Denmark, indicate potential fuel savings of up to 6.3% for boilers and 8.7% for marine four-stroke engines. In 2022, Scorpio Tankers allowed FOWE to test the system on one of their vessels, the STI Action, during a voyage from Borsel to Skagen. The results showed upwards of 10% fuel saving, more than proving its worthiness as an actionable step in the right direction.

When applying these results to the Scorpio Tankers’ fleet, conservative estimates on the overall savings across the fleet are 5% on overall operating costs; a reduction of 3% in fuel costs; and the prevention of 100,000 tons of carbon emissions annually. For Chairman and CEO, Emanuele Lauro, the results of the FOWE system fits perfectly with Scorpio’s core values of integrity, stewardship, sustainability, and moxie.

Making Waves

On 22 February 2024, Scorpio Tankers Inc. made a buzz in international news with the announcement to install FOWE’s Cavitech™ Technology across its entire fleet.

According to the Scorpio Tankers, Inc. press release, the terms of the licensing agreement will require no material upfront costs for the company, an added bonus. Mr. Lauro commented: “In terms of financial and environmental benefits, the FOWE system stands out for its clear and immediate advantages. Requiring little in the way of initial investment and eliminating the need for installation downtime, the FOWE solution presents an ideal pathway to reducing operating expenses and curbing greenhouse gas emissions.”

So, it makes fuel more efficient, reduces greenhouse emissions, protects the engine, and can be easily installed without large upfront fees. Is it a magic bullet? Let’s take a closer look at how the Cavitech™ system works.

According to the FOWE Eco Solutions website, water-emulsified fuels are an old and well-known idea but until now no one had developed the proper technology to stabilize a homogenous emulsion of fuel and water. The process that FOWE has developed enables cavitation of various materials with instantaneous mixing, heat treatment, dispersion, change of aggregate state structure, and activation of chemical bonds. The result is a completely stable fuel emulsion, with the ability to store it for at least 12 months without separation.

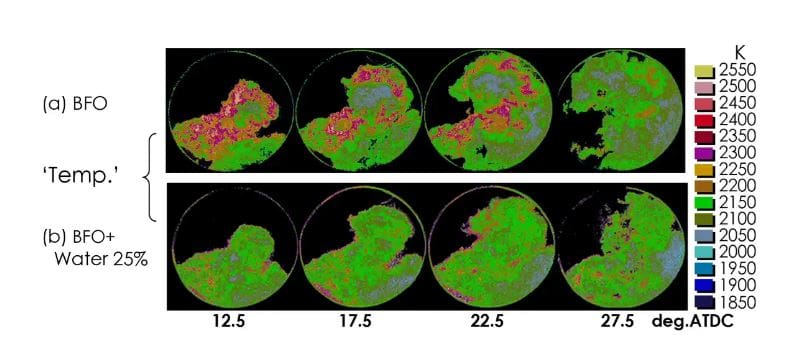

With the Cavitech system, the combustion of emulsified fuel is faster and produces higher average furnace chamber temperatures, without the local overheating that results in the development of Nitric Oxide. This makes the fuel combustion more stable and complete, therefore, the harmful greenhouse gasses aren’t produced, naturally making lower particle emissions. According to FOWE’s website, experiment and practice have proven that for every additional 1% of water in fuel oil the NOx emission is reduced by 1 to 1.5%.

For installation, the equipment is composed of a pump and regulation valves that can be easily installed in existing piping of combustion engines. The valves and heads are sized to fit on 100 mm pipelines and can be arranged in parallel for increased capacity. Depending on the fluids being processed, the specific design of the head and the operating pressure can be adjusted to produce optimal results, operating at almost any water concentration, however, the favored range for useful fuels is between 10% – 30% water content.

In the recently released Scorpio Tankers 2023 Sustainability Report, Mr. Lauro stated that installing the FOWE Cavitech System: “is a significant step towards enhancing our energy efficiency and reducing our carbon footprint. This initiative is in line with our commitment to the International Maritime Organization’s (IMO) and the Poseidon Principles’ goal of reducing carbon intensity by 40% by 2030, relative to 2008 levels. Assuming the Poseidon Principles’ 2008 baseline, we have achieved a reduction of over 30% and we are optimistic that the integration of FOWE devices will propel us closer to this ambitious target.”

Time will tell

For the overall savings to Scorpio vessels, time will tell the actual result in fuel and emission savings. But while the industry waits for a viable alternative to crude oil, the FOWE solution presents a clear and immediate technology for a reduction of GHG emissions not only for our own fleet, but also for the world’s largest refineries and heavy fuel engines.